As businesses and facilities strive for greater energy efficiency and cost savings, the role of kWh sub-meters has become increasingly vital. These devices provide granular insights into energy consumption across specific circuits, zones, or equipment, empowering users to monitor usage patterns, identify inefficiencies, and make informed decisions. However, the effectiveness of a sub-meter is directly tied to how well it is commissioned — especially when integrated into a larger metering system.

Let’s explore why commissioning kWh sub-meters is essential and the potential benefits it brings to energy management.

What Is Commissioning?

Commissioning involves the process of verifying sub-meters to ensure they are installed, configured, and functioning correctly.

This includes:

• Verifying wiring and connectivity.

• Ensuring seamless integration with a central metering system or Building Management System (BMS).

Without proper commissioning, even the most advanced sub-meters may fail to provide reliable or actionable data.

Why Commissioning Is Crucial

Ensures Accurate Data Collection

Accurate energy data is the cornerstone of effective energy management. Incorrectly installed or configured sub-meters can produce erroneous readings, leading to:

• Misdiagnosed energy inefficiencies.

• Incorrect billing allocations for tenants or departments.

• Skewed energy usage reports.

Commissioning verifies that the meter’s readings are precise and aligned with the system’s requirements, ensuring the data you rely on is trustworthy.

Validates System Integration

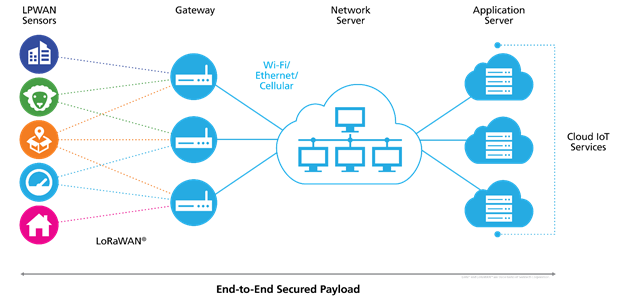

In many cases, kWh sub-meters are part of a broader metering or energy management system. Commissioning ensures that:

• The sub-meters are properly communicating with the central system.

• Data is being recorded and transmitted accurately.

• Integration protocols, such as Modbus or BACnet, are configured correctly.

This step is essential to enable seamless data aggregation and visualisation, allowing users to see the full picture of their energy usage.

Prevents Costly Errors

Incorrectly commissioned sub-meters can lead to costly issues, such as:

• Billing disputes with tenants or clients due to inaccurate measurements.

• Wasted time and resources troubleshooting problems after installation.

• Delays in achieving energy-saving goals due to unreliable data.

Proper commissioning identifies and resolves these issues early, preventing them from escalating into larger problems.

Supports Regulatory Compliance

Many industries require accurate sub-metering to comply with energy regulations, such as energy efficiency standards or carbon reporting mandates. Commissioning ensures that sub-meters meet these regulatory requirements and provide data suitable for audits or compliance reporting.

Maximises System Performance

When sub-meters are correctly commissioned, they work in harmony with the metering system to provide:

• Detailed energy profiles for specific areas or equipment.

• Real-time alerts for unusual consumption patterns.

• Actionable insights for reducing waste and optimising operations.

These benefits are only fully realised when the meters and system are properly set up and aligned.

Key Steps in the Commissioning Process

Pre-Installation Checks:

- Verify that the sub-meter is suitable for the intended application.

- Ensure compatibility with the central metering system.

Installation Verification:

- Confirm that the meter is installed in the correct location and wired properly.

- Check for secure connections and proper grounding.

Calibration and Testing:

- Conduct calibration tests to ensure the meter measures energy accurately.

- Perform functional tests to verify data transmission to the central system.

System Integration:

- Configure communication protocols and ensure data flows seamlessly into the metering.

- Test the display and reporting features to ensure usability.

Documentation and Handover:

- Provide detailed commissioning reports for future reference.

- Train the team on how to monitor and maintain the system.

The Long-Term Value of Commissioning

Commissioning is not just a one-time task — it’s an investment in the long-term reliability and effectiveness of your energy management system.

Properly commissioned kWh sub-meters:

• Deliver accurate data for years to come.

• Reduce operational costs by enabling precise monitoring and control.

• Provide peace of mind, knowing your energy system is functioning as intended.

Conclusion

In today’s energy-conscious world, kWh sub-meters are indispensable tools for monitoring and managing energy consumption. However, their value can only be fully realised when they are properly commissioned. By ensuring accuracy, validating integration, and preventing costly errors, commissioning lays the foundation for effective energy management and long-term savings.

If you’re installing or upgrading a metering system, don’t overlook the importance of commissioning. It’s the key to unlocking the full potential of your sub-meters and achieving your energy efficiency goals.